THE GASIFICATION

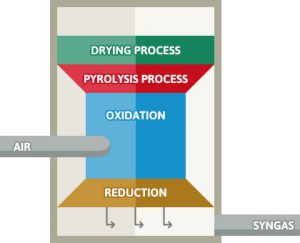

The gasifier employed is the one currently defined “Co-current fixed bed” gasifier. This type of gasifier consists of a closed tank; the chipped material is charged from the top. The syngas (produced gas) and the produced ashes leave from the reactor’s bottom. In such a system the material moves downwards, due to the gravity force.

During the descent the following reactions take place:

DEHYDRTTION OR DRYING PROCESS

In the dehydration zone, the water remaining in the chipped material evaporates. This step of the process takes place in air absence and needs heat energy. Temperature is inferior to 200°C.

THE PYROLYSIS (OR DEVOLATILIZATION) PROCESS

In this area, the wood separates at temperature between 200and 600°C by producing char and a gas mixture which includes also a great part of tar. Also this step of the process takes place in air absence and needs heat energy.

OXIDATION

In their descent inside the gasifier pyrolysis products enter in a narrowing where a controlled amount of air is injected. In this area the tar and a part of the charcoal are burned at temperatures above 1000 ° C.

This reaction provides the heat necessary in order the reactions in the remaining zones of the gasifier to take place.

This type of gasifier ensures an extremely low tar content in the syngas, in fact the tar generated in the pyrolysis is decomposed almost completely when passing the narrow and high temperature oxidation zone.

REDUCTION

In this area the charcoal, supported by a grid, reacts with the gas resulting from the oxidation zone that maintain temperatures above 700 ° C. The reactions that occur in this area allow to obtain a further portion of combustible gases (mainly CO and H2), transforming the water vapour coming from drying and oxidation, the carbon dioxide generated in the oxidation zone and the charcoal.

After emerging from the gasifier the flow of gas and ash is cooled to about 130 ° C through a series of heat exchangers. The recovered heat is used in part to heat the air used for the oxidation. The remainder part heats a flow of hot water which is supplied from plant as cogenerated heat.

The gas flow then passes through a dry filter in which the ash is separated from the syngas. The filter is equipped with automatic extraction auger, which carries the ashes in a closed tank. .

The clean syngas is then burned in an Otto cycle engine to produce electricity. The engine cooling is done with a water-water exchanger, thereby further contributing to the production of hot water.

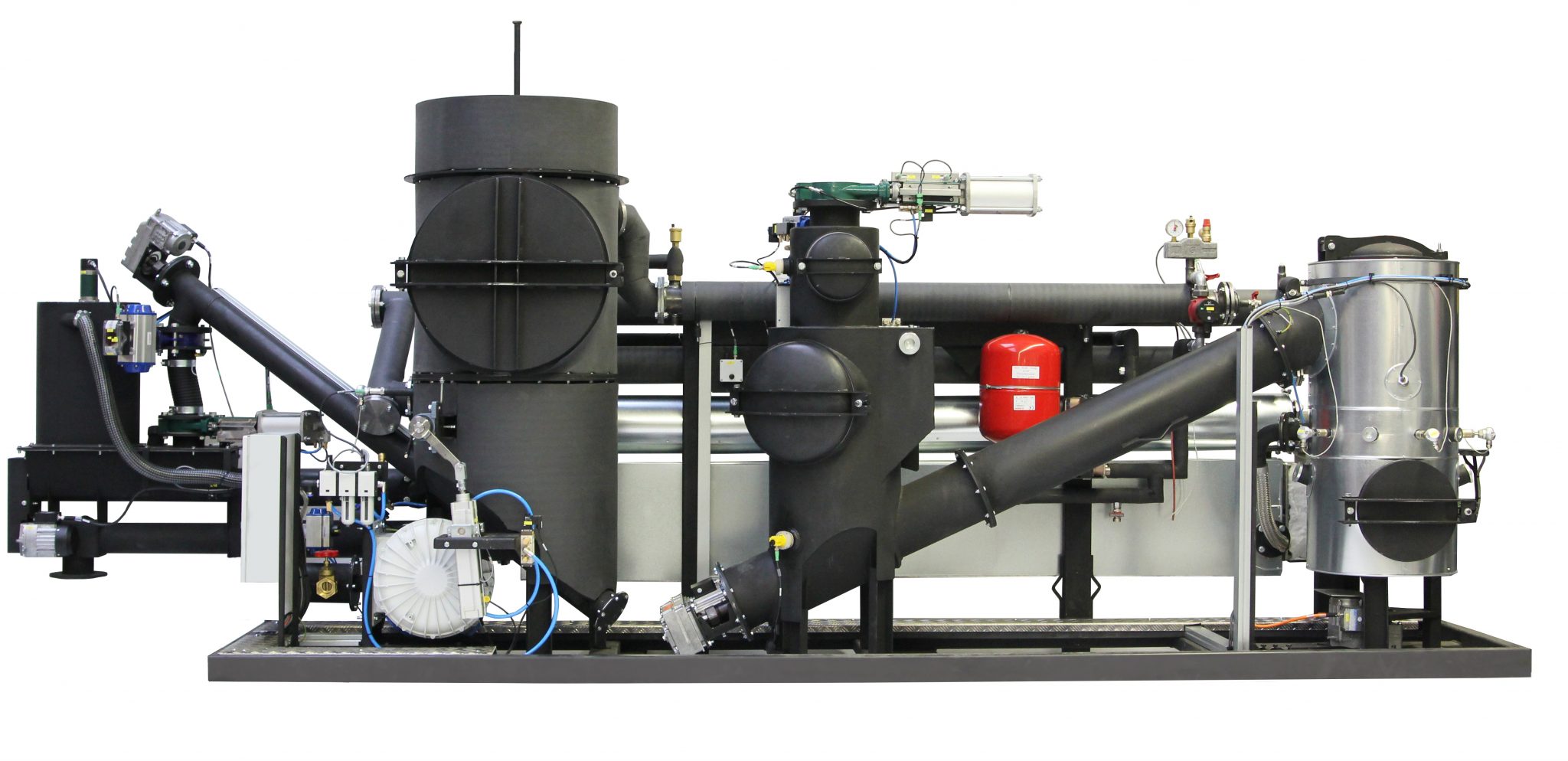

Gasification unit SPANNER RE 2

Cogenerator SPANNER RE2, with 8 L motor