PEZZOLATO CUTTING TECHNOLOGY

Pezzolato drum chippers cutting technology allows producing prime quality chips, deriving not only from logs but from branches, sawmill wastes and low-value material as well.

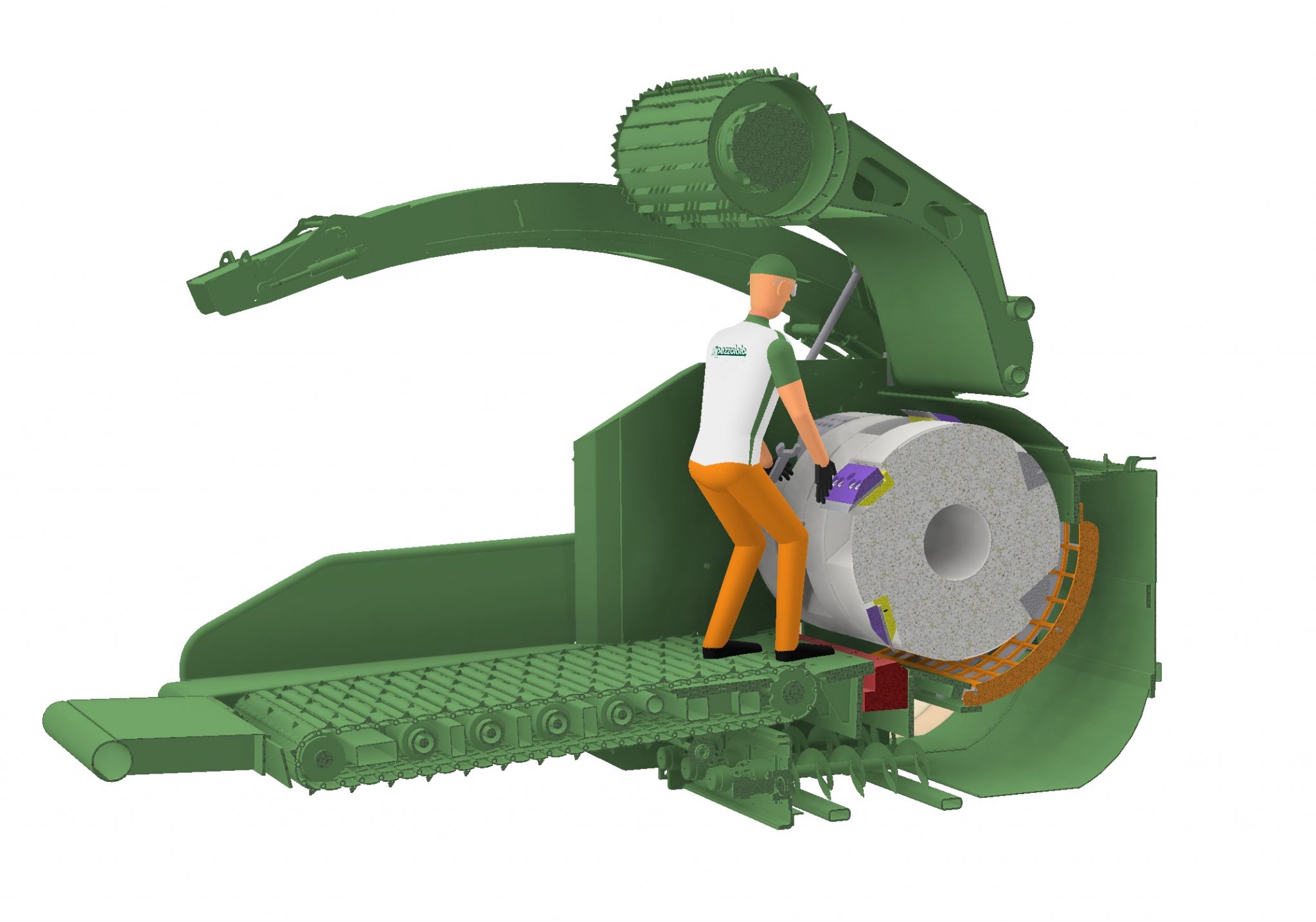

The cutting system used by Pezzolato consists of a closed stagger sections drum equipped with knives, a counter-blade and a sieving grid with interchangeable calibration.

This system assures the production of quality chips since the closed drum keeps the chips cutting length fixed and constant. The wood undergoing the knife action is transformed into calibrated chips, which can pass through the calibration grid immediately after the cut.

Once the distance between the blade and the drum (i.e. the cutting length) is set, the material is always cut in the same size each time the blade passes, thus ensuring high quality chips even when deriving from branches or by-products. In the so-called “open” drum chippers, the material can be dragged by the drum and then cut beyond the maximum size. Thanks to the Pezzolato technology, the closed drum acts as a barrier and aligns the material, preventing to produce chips larger than required.

Once the distance between the blade and the drum (i.e. the cutting length) is set, the material is always cut in the same size each time the blade passes, thus ensuring high quality chips even when deriving from branches or by-products. In the so-called “open” drum chippers, the material can be dragged by the drum and then cut beyond the maximum size. Thanks to the Pezzolato technology, the closed drum acts as a barrier and aligns the material, preventing to produce chips larger than required.